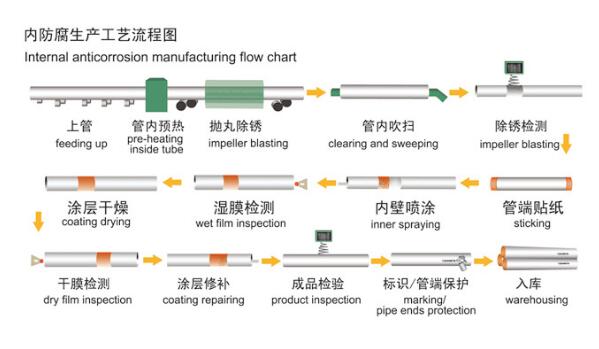

The product description:

Steel pipe anticorrosion production line equipment is mainly used in oil, gas, water, sewage and other liquid conveying tube wall of steel pipe anticorrosion coating processing production, can be carried out liquid epoxy coating anticorrosive epoxy powder anticorrosive, wall, wall solvent-free coating anticorrosion. Its anti-corrosion production process and product performance, fully meet: CHPP cc01 SPE - 100000-03, solvent-free QCNPC - GD0291-2006, and China‘s urban construction industry standard (CJ/T120-2008 technical standards at home and abroad such as anti-corrosion standards.

1、Steel tube wall flame preheating equipment

Within the equipment function: derusting, through the flame, heating pipe inner surface to 40 ℃, 60 ℃, remove the moisture on the surface of the steel pipe, oil pollution; In order to shot blasting treatment.

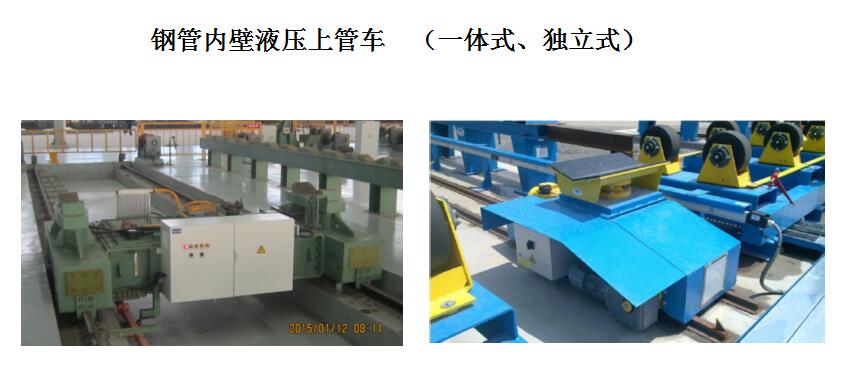

2、The hydraulic pipe car

Pipe car a set of two (points one-piece and two independent type), to realize automatic steel pipes with location between the mobile and automatic control. The car move speed: the biggest < / span > 30 m/min (according to actual); Can, according to the needs of process between each station automatic transmission pipe, realize nobody care operation, put an end to safety accidents.

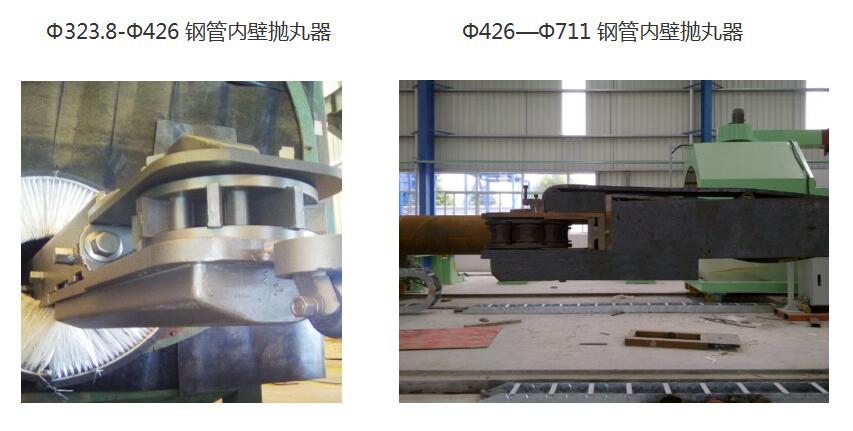

3、The lining of blast cleaning machine(Ø 323.8- Ø 3600)

Device description:

Advanced shot blasting derusting machines and one-click automation control, choose one of the world‘s most advanced equipment parts and Siemens control system, the mature technology and production experience.

Through efficient mechanical hydraulic blasting process way to clean up for the inner surface of steel pipe scale, rust, etc., make the surface presents metal color, and its surface has a certain roughness, improve the coating bond strength, but also can improve the fatigue strength of steel pipe; The machine is driven by hydraulic blasting device with high efficiency, bucket elevator, turn tube system, pills for centralizer, sand separation, automatic feed system, recycling belt system, Germany imported hydraulic system, electrical control with one button, dust removal system, etc.

The main performance specification is as follows:

Steel pipe inner surface shot blasting machine: 3 sets, suitable diameter 323.8 Φ426, 426-711 and 720 - Φ Φ 3200, the highest efficiency of rust removal of 300 m2 / Hr. Highest shot blasting machine speed can reach 6500 r/min (2500-6500 r/min can be adjusted).

Steel tube wall centralizer: 3 sets, suitable diameter 323.8-426, 426 - Φ Φ 711, 711 and 720 -Φ

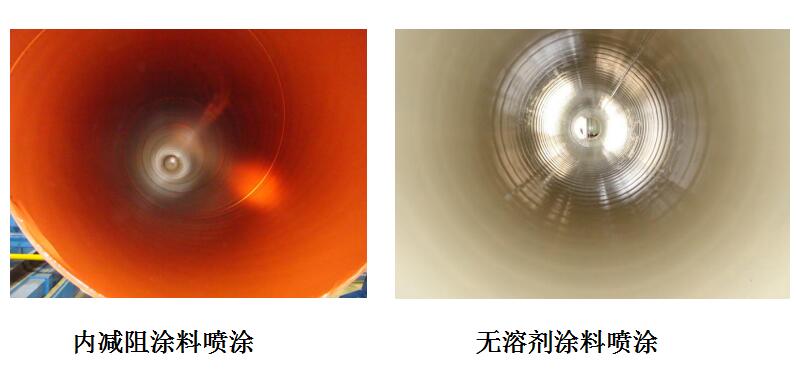

4、Steel tube wall painting line

Through the way of airless spraying equipment descriptions two-component liquid epoxy coating, solvent-free epoxy coating thickness in accordance with the provisions of the uniform spray to the inner surface of steel pipe.

High-pressure airless spraying pump driven by high pressure gas coating, the coating to high pressure, through the narrow nozzle, produce negative pressure, severe inflation, make the paint form very fine fan-shaped fog, high speed spray to the workpiece surface membrane layer. Due to high-pressure airless spraying pressure is high, and there is no air in the coating, so as to improve the quality of the paint film, coating evenly, pinhole, spraying with high-pressure airless spraying method, the spray gun with the front end of the boom, axial movement along the pipe, the pipe rotation.

Spray pump and material storage tank is fixed on the car, spray gun with the front end of the boom, boom height is adjustable, to adapt to the requirements of different diameter steel pipe type reducer with the car in the shaft will move forward along the pipe axis, driven by the process to the steel pipe blowing, return the car spraying operations.

Steel tube on both ends of the shield (including fixed protection, and mobile shield) will be closed and dust removal equipment connection on both ends of the pipe, the exhaust emissions standards.

5、Steel pipe system

6、Solvent evaporation system

Device description:

Paint mist treatment device is divided into mist filtering device and the harmful gas adsorption device。

Paint mist filtering device

Dry filter device adopts mist filter paper to paint mist filtering, its free maintenance for one year. Produced by spray paint room and dry room paint mist classics drying chamber pit gas, pipeline by inhaling mist filter box, after paint mist filters, fan inhaled by activated carbon adsorption device for harmful gas adsorption or burning.

The harmful gas adsorption device

Harmful gas adsorption device to benzene, alcohols, ketones, esters, gasoline exhaust gas of organic solvent such as adsorption, suitable for large volume low concentration of exhaust gas treatment. This device is mainly composed of adsorption van body, stop valve, filters, fan motor, etc, the air inlet is equipped with the regulator.

7、Steel pipe inner surface curing furnace

Device description:

Use natural gas or fuel provide heat source heating way, curing furnace wall and furnace top with heat insulation material, inlet and outlet pipe by the oven door closed, with two gas combustion machine, furnace for hot air, temperature in a 50-60 ℃, temperature adjusting range 50-90 ℃, the coated steel pipe inside the furnace after stay for about 30 to 50 minutes (according to coating specific time), in order to curing coating.

8、Steel pipe wall corrosion curing furnace, chain plate conveyor equipment

Chain plate conveyor equipment structure is compact, reliable, and can effectively reduce the labor intensity of production line workers and on-site security risks, a large number of reducing staff into the internal moving tube production line, improve the efficiency of the production line and advanced, automatic into the tube, is a leading international steel pipes conveying form.

9、Steel tube wall of epoxy powder coating (internal and external epoxy powder, powder 3 PE) FBE anti-corrosion production process description:

After inspection of steel pipes from feeding platform into the derusting transmission line. Drive go round steel tube derusting the transmission line, in turn, through the fuel preheating furnace and derusting machine cleaning.

Through the outer wall after sand outside the steel pipe through the transmission line of the first platform position by a hydraulic lifting pipe after the car sent to the front of the blasting in GuanPing waiting for wall blasting machine processing, hydraulic car automatically return to the original location, at the same time inside blast pipe hydraulic pipe rising car carry steel pipe shot location and then automatically go back to the wall, wall blasting began blasting at the same time, the lining of blast after processing of steel pipe after hydraulic pipe transport cars to purge location in the lining of purging, hydraulic pipe purging of finished steel pipe and the car to the inner wall of epoxy powder coating line, at the same time the lining of powder coating mobile car drive coating cantilever began to fast forward, when the steel pipe spiral progress to the intermediate frequency heating coil, heating to a suitable temperature wall spraying trolley jib head also to the position and velocity of gun down to the same speed as steel tube speed automatically, after the steel tube and the spray gun to go forward to the powder room wall epoxy powder spray gun to spray end mobile car stop at the same time, the side wall of steel pipe forward at the same time the transmission line recycling car started to move in the direction of steel tube forward movement until the end of a pole out of intermediate frequency after stop and returned to the original location, at the same time automatic spraying mobile car and cantilever also returned to the original position; Steel tube has been forward to the next tube position, tube hydraulic pipe under the car began to work, rise hydraulic and transfer pipe to the outside to the outer wall of steel pipe anticorrosion line 3 PE anticorrosion.